Brands Harnessing the Power of 3D Printed Fashion

Summary

Reflection Questions

Journal Prompt

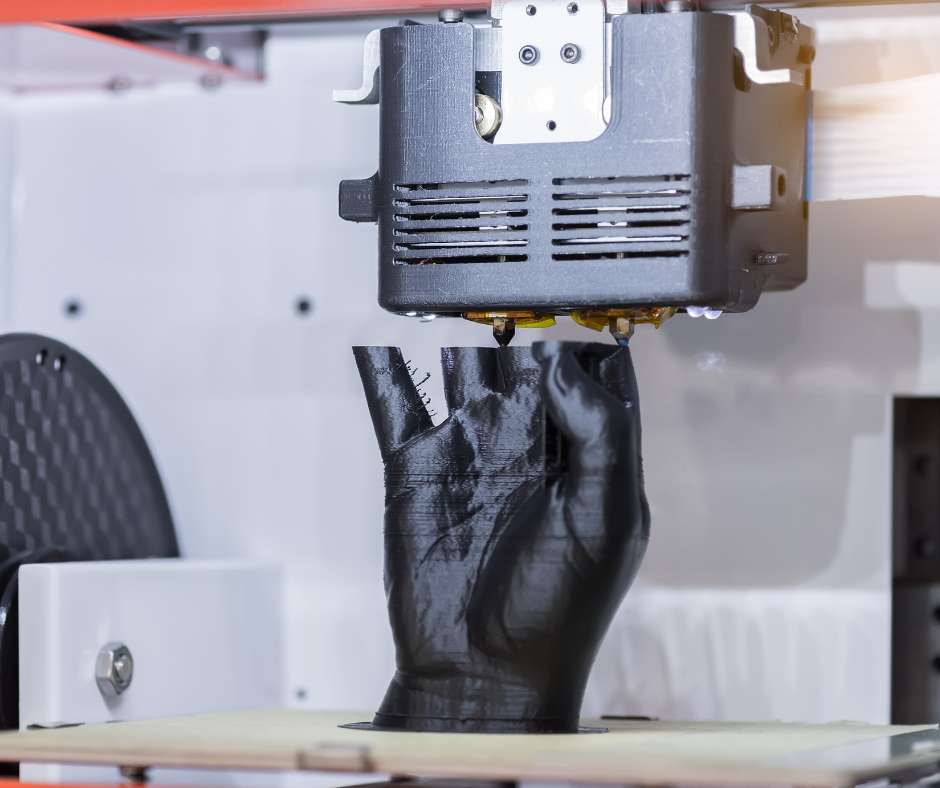

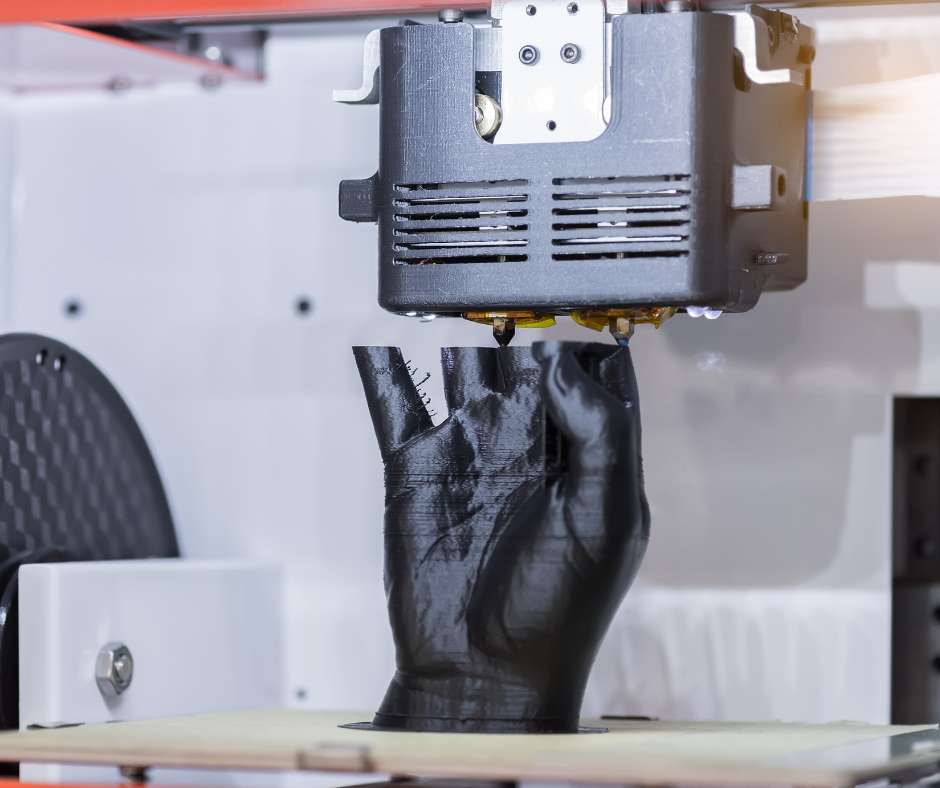

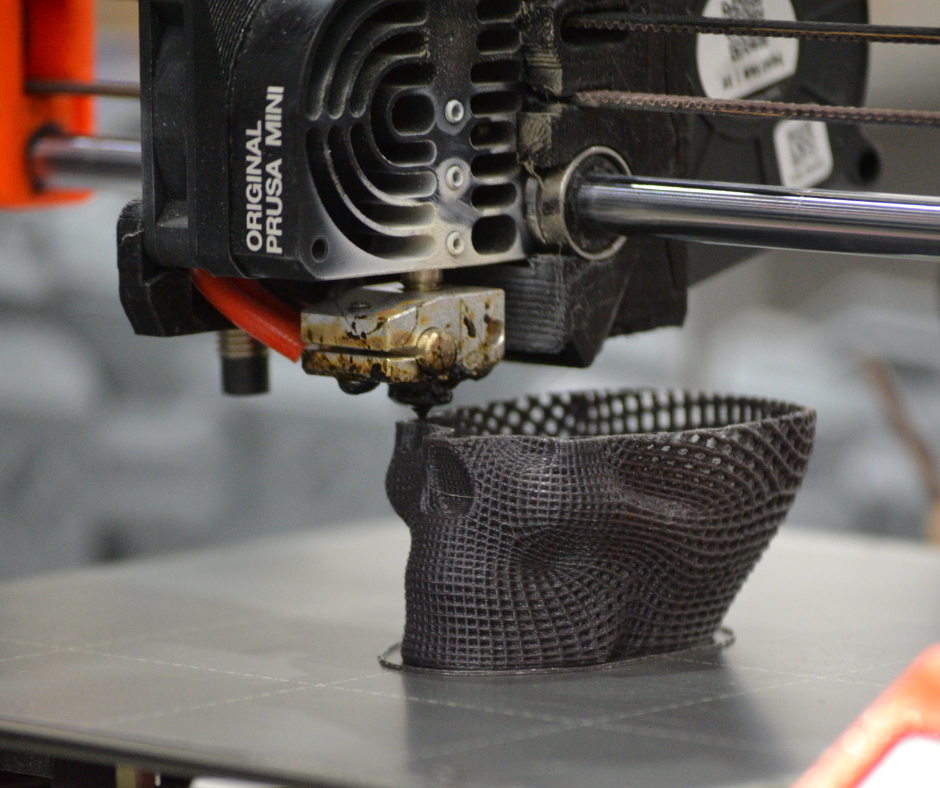

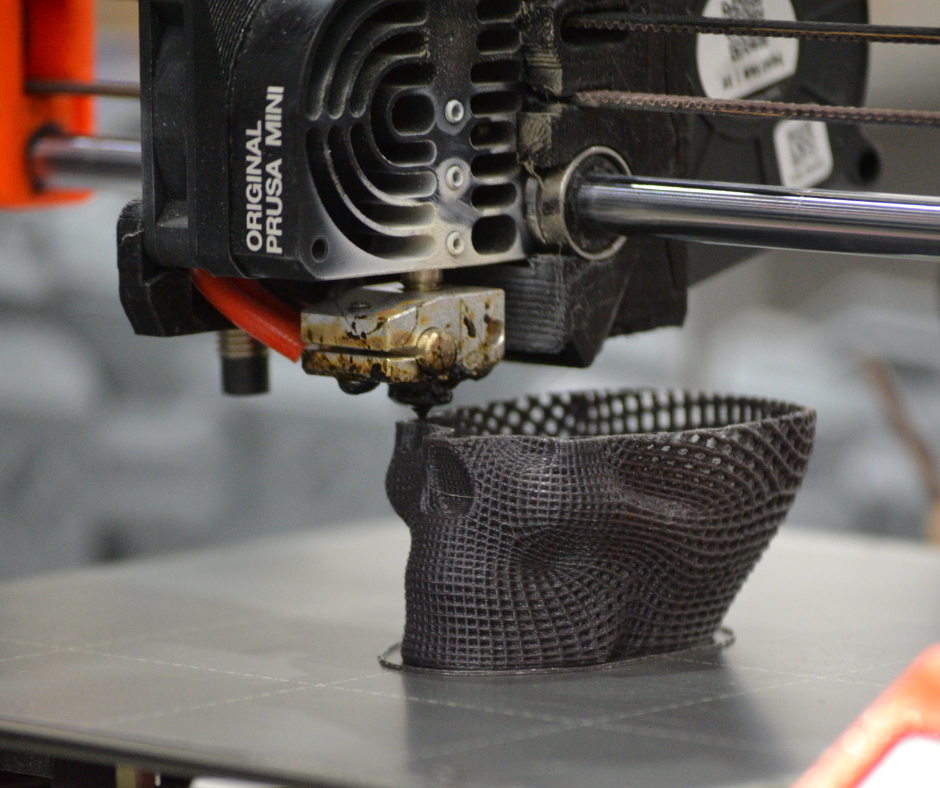

A form of additive manufacturing, 3D printing has gained traction in the fashion industry over the last decade. Offering adaptable prototype development, unparalleled customization, enhanced sustainability, and the opportunity to experiment with different materials, 3D printed fashion appeals to both consumers and designers. Below are a number of fashion brands currently using 3D printing to create incredible designs that reduce waste while perfectly suiting each wearer. From Adidas to Dior, read on to learn more!

The Benefits of Using 3D Printing in Fashion Design and Manufacturing

3D printing offers a multitude of benefits in the fashion industry, transforming traditional processes and opening new avenues for innovative designs and creativity. This technology allows designers to push the boundaries of complexity and precision, enabling the creation of designs that were previously unachievable with conventional methods. Let’s take a look at some of the benefits this technology offers to designers and consumers alike.

Adaptable Prototype Development

One of the most significant advantages of additive manufacturing in fashion is the ability to prototype rapidly. Designers can quickly move from concept to physical product, experimenting with different shapes, sizes, and materials without the need for expensive molds or cutting tools. This not only speeds up the design process but also reduces costs, making it easier for designers to refine their products and bring new ideas to market more quickly.

Unparalleled Customization Opportunities

Furthermore, 3D printing supports a high degree of customization, which is increasingly demanded by consumers seeking unique and personalized products. With 3D scanning technologies, garments and accessories can be tailored to fit an individual’s exact measurements, ensuring a perfect fit and adding a level of personalization that enhances consumer satisfaction and comfort.

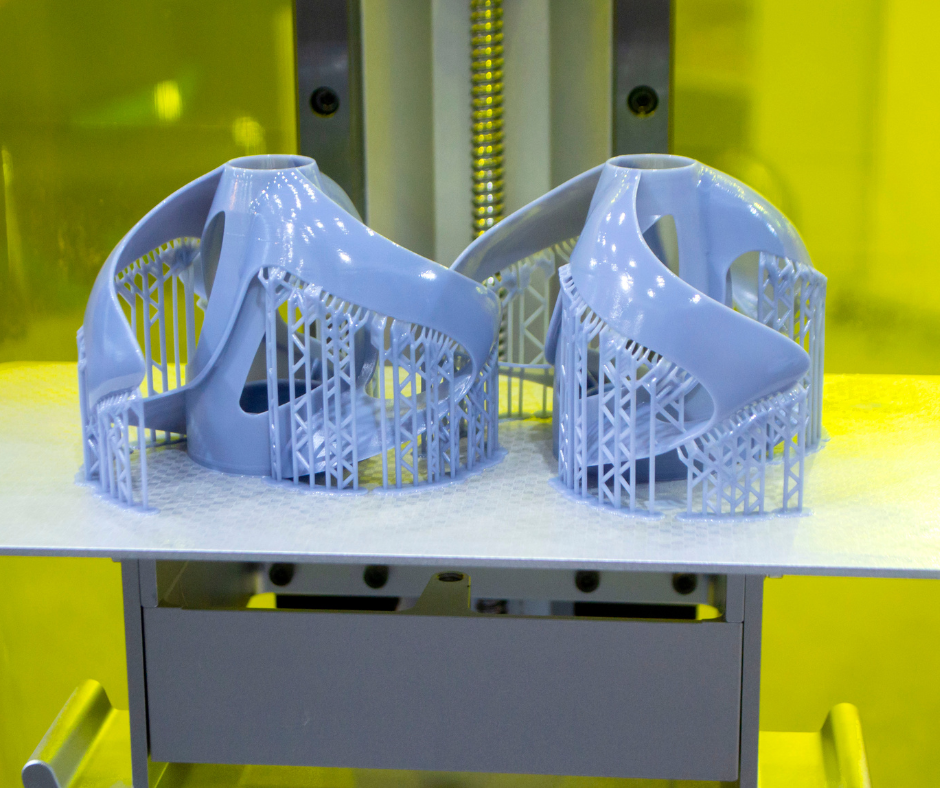

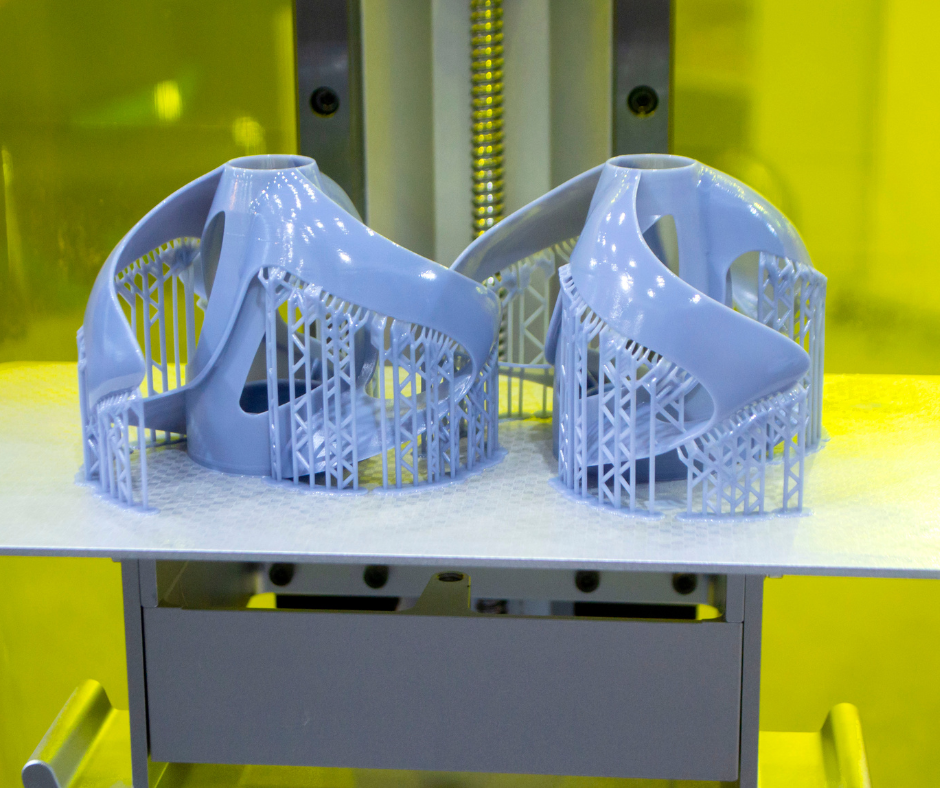

Sustainability and Reduced Environmental Impact

We all know how horrible fast fashion is for our planet. Sustainability is another critical area where 3D printing can make a significant impact. Traditional fashion manufacturing is often resource-intensive and wasteful, with substantial amounts of excess fabric and various materials discarded and energy consumed.

In contrast, 3D printing minimizes waste and reduces the need for excess inventory by using only the amount of material necessary to create the product, and many 3D printers can use recycled materials, reducing the environmental footprint of production. Moreover, the ability to produce clothes on demand can diminish the need for large inventory stocks, thereby lessening the risk of overproduction and excess waste.

The Ability to Experiment with Different Materials, New Techniques, and the Latest Innovations in Tech

From a creative standpoint, 3D printing enables designers to experiment with intricate designs and complex structures that would be challenging or impossible to achieve through traditional textile manufacturing. This capability fosters innovation in texture, form, and function, allowing for the creation of garments that can change shape or color in response to environmental stimuli, or integrate seamlessly with wearable technology. The aesthetic possibilities are nearly limitless, providing a new canvas on which designers can express their artistic visions.

Brands Using 3D Printing to Create Garments and Explore New Materials

Nike

While not strictly part of the fashion industry given its focus on athletic wear, Nike has been at the forefront of incorporating 3D printing technology into its design and manufacturing process—particularly in prototyping. By utilizing 3D printing, Nike can rapidly produce and test various iterations of shoe designs, allowing designers to quickly refine and perfect their creations. This speed and flexibility in prototyping enable Nike to bring innovative and high-performance footwear to market faster than traditional methods would allow.

Additionally, Nike has explored using this groundbreaking technology to customize footwear for individual athletes. By scanning athletes’ feet and utilizing 3D printing technology, Nike can create personalized shoes tailored to the individual’s unique biomechanics and preferences, enhancing comfort and performance on the field or court.

Moreover, Nike has also experimented with 3D printing in the production of specialized components for its footwear. One notable example is the development of 3D-printed midsoles, which offer enhanced cushioning and support while reducing weight. This approach allows Nike to optimize the design and performance of its shoes, catering to the specific needs of athletes across different sports and activities.

Adidas

Adidas has been leveraging 3D printing technology in several aspects of its design and manufacturing processes to innovate within the footwear industry. One prominent use of 3D printing at Adidas is in the creation of prototypes. By employing 3D printing, Adidas can swiftly produce prototype models of shoes and components, allowing designers to iterate designs quickly and efficiently. This agility in prototyping enables Adidas to explore new design concepts and materials, leading to the development of innovative and high-performance footwear that meets the evolving needs of athletes and consumers.

Like Nike, Adidas has been exploring the use of 3D printing to produce custom footwear tailored to individual athletes. Through advanced scanning and analysis techniques, Adidas can gather precise data on an athlete’s foot shape, gait, and biomechanics. This data is then utilized to design and manufacture personalized shoes using 3D printing technology, ensuring a perfect fit and optimized performance for the wearer. By integrating 3D printing into its customization process, Adidas can offer athletes a level of comfort, support, and performance that is unparalleled in the industry, demonstrating the brand’s commitment to innovation and personalized solutions in athletic footwear.

Under Armour

Under Armour has embraced 3D printing technology to drive innovation in its design and manufacturing processes, particularly within the realm of athletic apparel and footwear. One key application of 3D printing at Under Armour is in prototyping. By utilizing 3D printing, the brand can rapidly produce and iterate on prototypes of apparel and footwear designs.

This allows designers to experiment with different shapes, structures, and materials, facilitating the creation of cutting-edge products that meet the performance needs of athletes. The ability to quickly prototype with 3D printing enables Under Armour to stay agile and responsive to consumer demands, bringing innovative and high-quality products to market faster than traditional manufacturing methods would allow.

Chanel

Chanel, renowned for its elegance and innovation in fashion, has adopted 3D printing technology to push the boundaries of design in accessories and jewelry. One significant way Chanel utilizes 3D printing is in the creation of intricate and complex pieces that would be challenging or impossible to achieve through traditional manufacturing methods.

By harnessing the precision and versatility of 3D printing, Chanel’s designers can explore new forms, textures, and geometries, resulting in unique and avant-garde accessories that captivate the imagination. This approach enables Chanel to maintain its reputation for exquisite craftsmanship while embracing modern technology to create truly distinctive pieces that resonate with contemporary consumers.

Additionally, Chanel has utilized 3D printing to streamline its design and production processes, enhancing efficiency and reducing lead times. By incorporating 3D printing into its workflow, Chanel can iterate designs more quickly and produce prototypes with greater speed and accuracy. This agile approach to design and prototyping allows Chanel to respond rapidly to changing trends and consumer preferences, ensuring that its collections remain fresh and relevant in a fast-paced fashion landscape.

Dior

Dior incorporates 3D printing technology primarily in its avant-garde designs and accessories, pushing the boundaries of traditional fashion with innovative techniques. The brand utilizes 3D printing to create intricate and elaborate pieces that showcase a fusion of craftsmanship and modern technology.

By harnessing the capabilities of 3D printing, Dior’s designers can realize complex geometries and structures that would be challenging to achieve through traditional manufacturing methods alone. This approach allows Dior to craft stunning and futuristic fashion pieces that captivate audiences and cement the brand’s reputation as a pioneer in luxury fashion.

Fuel your creative fire & be a part of a supportive community that values how you love to live.

subscribe to our newsletter

United Nude

United Nude has embraced 3D printing primarily in their footwear designs, merging fashion with technology to create intricate and visually striking shoes. They are known for collaborating with architects and designers to explore new forms and structures, which are often produced through 3D printing to achieve complex geometric shapes and patterns that traditional methods cannot replicate.

One of the most famous collaborations was with architect Zaha Hadid to create the Nova Shoe, which featured a fluid design made possible through 3D printing technologies. This shoe was part of a limited edition collection that showcased the potential of combining architecture and fashion with advanced manufacturing techniques.

XYZ Workshop

XYZ Workshop operates at the intersection of architecture, fashion, and design, utilizing 3D printing to create wearable art and home decor. Their approach often involves open-source designs, allowing others to experiment and fabricate their creations.

They gained significant attention with their “InBloom Dress,” which was created in collaboration with Ultimaker. This dress is composed of 3D printed panels that are assembled to create a flexible and wearable piece, reflecting both aesthetic appeal and practical application of 3D printing in fashion.

Balenciaga

Balenciaga has incorporated 3D printing into their high fashion garments, particularly in creating structured and futuristic clothing items. By using 3D printing, Balenciaga is able to experiment with unconventional materials and intricate designs that add a unique texture and shape to their collections, pushing the boundaries of traditional fashion design.

For their Fall 2018 collection, Balenciaga introduced a line of coats and dresses that featured 3D printed bases, which were then molded and fused with traditional fabrics to create high-fashion garments. This process allowed for precise tailoring and complex shapes that are difficult to achieve through conventional methods.

Puma

Puma has utilized 3D printing technology to innovate in the creation process of athletic shoes. They focus on improving performance through customizing midsoles that are tailored to an athlete’s foot, providing enhanced cushioning and support. This customization is achieved using data-driven analysis and 3D printing, allowing for rapid prototyping and iterative testing.

The brand developed the “Puma x MIT Design Lab Futurecraft Shoe,” which used biodesign to incorporate living organisms and biodegradable materials in the shoe manufacturing process. While not entirely 3D printed, the project included 3D printed components that aimed to enhance athletic performance by reacting to an athlete’s body data in real-time. This project also shows how 3D printing can help bring sustainable alternative materials to market.

New Balance

New Balance uses 3D printing primarily for developing advanced athletic footwear. Their focus is on creating custom-fit shoes with optimized performance characteristics, such as enhanced cushioning and precise fit. 3D printing allows New Balance to rapidly prototype new designs and materials, speeding up the development process and offering tailored solutions for athletes.

Reebok

Reebok has integrated 3D printing into their production process to innovate and speed up the design of sports equipment and footwear. Their use of 3D printing has enabled them to develop more customized and technical products with complex structures that provide better performance and comfort, especially in their high-performance athletic shoes.

Their Liquid Factory initiative, which includes 3D printing, was highlighted by the release of the Liquid Speed shoe. This shoe uses 3D printing not just for prototyping but also in the final product, particularly in the unique outsole that is drawn directly onto the shoe in three-dimensional layers.

Nervous System

Nervous System creates jewelry, art, and housewares inspired by natural phenomena and scientific research. They utilize 3D printing to produce items that are computationally generated, featuring complex patterns and forms that mimic processes seen in nature. Their approach allows for the creation of unique, customizable products that are both functional and aesthetically unique.

Their Kinematics Dress is a significant example, which is a fully articulated garment created from thousands of interconnected pieces, all printed as one single folded piece. This dress can be custom-fitted to the wearer’s body through 3D scans and is designed to provide detailed aesthetic and functional customization.

Francis Bitonti Studio

Francis Bitonti Studio is renowned for merging fashion with technology, particularly through the use of 3D printing. The studio is famous for designing the 3D printed Dita Dress. They focus on pushing the boundaries of digital fabrication in luxury goods, exploring new aesthetic possibilities with materials and forms that are enabled by 3D printing technology.

Anouk Wipprecht

Anouk Wipprecht, a fashion tech designer renowned for her groundbreaking work at the intersection of fashion and technology, extensively incorporates 3D printing in creations that wow the fashion world. Wipprecht leverages 3D printing to fabricate intricate and dynamic components that integrate seamlessly with her designs, blurring the lines between fashion, art, and technology.

By harnessing the precision and flexibility of 3D printing, she is able to realize visionary concepts that push the boundaries of traditional fashion. Wipprecht’s innovative use of 3D printing not only allows her to create garments and accessories with unparalleled aesthetics but also enables her to explore new forms of interaction and expression within the realm of wearable technology.

Anouk Wipprecht’s Spider Dress

Anouk Wipprecht’s “Spider Dress” is a remarkable piece of wearable technology that combines fashion design with interactive elements. The Spider Dress is inspired by the natural world, specifically the behavior of spiders, which use their limbs to detect and react to their environment. Wipprecht’s design features a striking silhouette adorned with robotic spider-like limbs that are equipped with sensors and actuators.

The sensors embedded within the Spider Dress detect the wearer’s biometric data, such as their heart rate and respiration. These sensors enable the dress to respond dynamically to the wearer’s physiological state and the surrounding environment. For example, if the sensors detect that the wearer is feeling stressed or anxious, the robotic limbs may extend defensively, creating a physical barrier around the wearer. Conversely, in moments of calmness or relaxation, the limbs may retract or move gracefully, enhancing the overall aesthetic of the dress.

While the Spider Dress itself is not entirely 3D printed, it does incorporate 3D printing technology for certain components, particularly the intricate structures and robotic elements. While the dress may include traditional fabric materials for the main body, the robotic limbs and other embellishments are crafted using 3D printing techniques. These 3D-printed components are then integrated into the overall design to create the desired aesthetic and functionality, showcasing Wipprecht’s skillful blend of fashion design and cutting-edge technology.

Iris van Herpen

Iris van Herpen, a pioneer in merging fashion with technology, extensively utilizes 3D printing in her avant-garde haute couture creations. Van Herpen employs 3D printing to fabricate intricate and sculptural elements that defy traditional notions of garment construction. By harnessing the precision and versatility of 3D printing, she is able to realize visionary designs that push the boundaries of fashion.

Van Herpen’s innovative use of 3D printing enables her to experiment with unconventional materials and create garments with surreal forms and textures, blurring the lines between art, fashion, and science. Her exploration of 3D printing as a design tool not only challenges the conventions of the fashion industry but also opens up new possibilities for artistic expression and craftsmanship.

Final Thoughts on Additive Manufacturing in the Fashion Industry

The integration of 3D printing into fashion design and manufacturing heralds a new era of innovation and sustainability. This technology not only empowers designers with the tools to unleash unprecedented creativity but also addresses some of the most pressing challenges in the industry, such as waste reduction and resource efficiency.

As brands from Balenciaga to New Balance continue to explore and expand 3D printed fashion, they are not just revolutionizing the way garments are created and customized but are also setting new standards for the future of fashion. With its ability to merge aesthetic exploration with environmental consciousness, 3D printed fashion has unparalleled potential, pushing the boundaries of what’s possible in fashion while promoting a more sustainable and personalized approach to garment production.

Design Dash

Join us in designing a life you love.

-

All About Our 7-Day Focus & Flex Challenge

Sign up before August 14th to join us for the Focus & Flex Challenge!

-

Unique Baby Names Inspired by Incredible Women from History

Inspired by historic queens, warriors, artists, and scientists, one of these unusual baby names might be right for your daughter!

-

Finding a New 9 to 5: How to Put Freelance Work on a Resume

From listing relevant skills to explaining your employment gap, here’s how to put freelance jobs on your resume.

-

What is Generation-Skipping, and How Might it Affect Sandwich Generation Parents?

The emotional pain and financial strain of generation skipping can be devastating for Sandwich Generation parents.

-

Four Material Libraries Dedicated to Sustainability, Preservation, and Education

From sustainable building materials (MaterialDriven) to rare pigments (Harvard), each materials library serves a specific purpose.

-

Do You Actually Need a Beauty Fridge for Your Skincare Products? (Yes and No.)

Let’s take a look at what dermatologists and formulators have to say about whether your makeup and skincare belong in a beauty fridge.